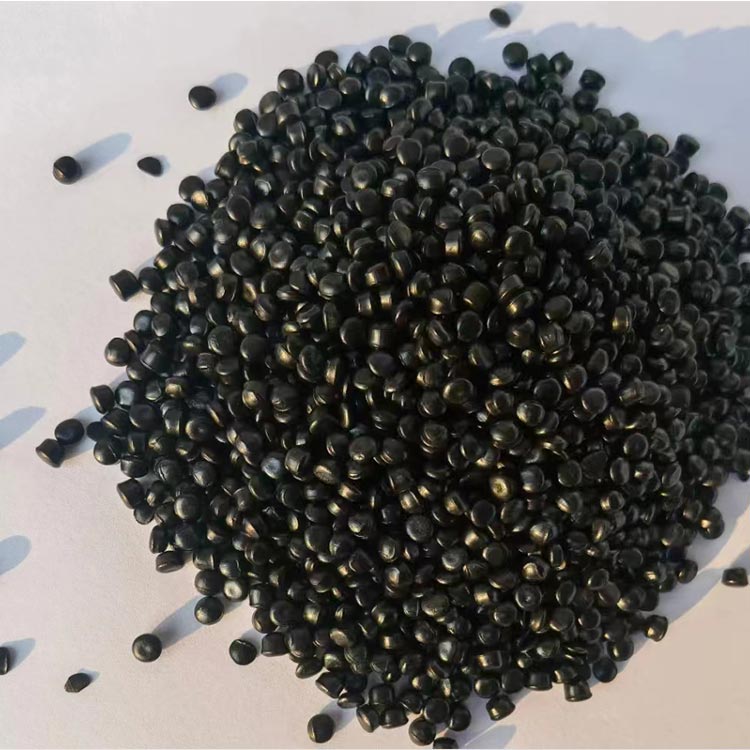

无载体黑色母粒是一种高质量的颜料,由于它具有优异的光谱性能和抗氧化性能,因此在许多领域得到了广泛的应用。它是一种高性价比的颜料,在塑料、涂料、橡胶、印刷等行业中具有广泛的应用。

一、无载体黑色母粒的基本特点

无载体黑色母粒是一种颜料,主要由碳黑和添加剂组成。其主要特点如下:

1.高纯度:无载体黑色母粒采用高纯度的原材料制成,不含杂质和金属,可以保证产品的质量和稳定性。

2.优异的光谱性能:无载体黑色母粒具有极佳的光谱性能,可以吸收光的大部分颜色,使被吸收的颜色更加明亮鲜艳。

3.良好的稳定性:无载体黑色母粒具有极佳的稳定性,可以在不同的温度和湿度条件下保持稳定的性能。

4.卓越的耐热性:无载体黑色母粒具有极佳的耐热性,可以在高温环境下保持稳定的颜色和光谱性能。

二、无载体黑色母粒的应用领域

无载体黑色母粒主要应用于以下几个领域:

1.塑料行业:由于无载体黑色母粒具有优异的光谱性能、稳定性和耐热性,因此在塑料制品中广泛应用,如塑料容器、管材、鞋子等。

2.涂料行业:无载体黑色母粒可以用于涂料中,可以提高色泽度和光泽度,保持涂层的稳定性和耐磨性。

3.橡胶行业:无载体黑色母粒可以用于橡胶制品中,可以提高橡胶的黑度和均匀性,使制品更加美观,也可以提高橡胶的耐热性、耐氧性和耐臭氧性。

三、无载体黑色母粒制备工艺

无载体黑色母粒的制备工艺主要包括以下几个步骤:

1.选用优质碳黑作为原材料,并加入特定的添加剂,如稳定剂、流平剂等,以提高产品的品质和稳定性。

2.在混合机或高剪切混合器中,将原材料混合均匀。

3.将混合后的原材料做成颗粒状,可采用压片机、挤出机等设备。

4.将颗粒状的无载体黑色母粒进行筛选和包装,制成成品。

Carrier-free black masterbatch is a high-quality pigment that is widely used in many fields due to its excellent spectral properties and antioxidant properties. It is a cost-effective pigment with a wide range of applications in plastics, coatings, rubber, printing and other industries.

I. Basic characteristics of carrier-free black masterbatches

Carrier-free black masterbatch is a kind of pigment, mainly composed of carbon black and additives. Its main features are as follows:

1. High purity: carrier-free black masterbatch is made of high-purity raw materials, free of impurities and metals, which can guarantee the quality and stability of the products.

2. Excellent spectral properties: carrier-free black masterbatches have excellent spectral properties, which can absorb most of the colors of light and make the absorbed colors brighter and more vivid.

3. Good stability: carrier-free black masterbatches have excellent stability and can maintain stable performance under different temperature and humidity conditions.

4. Excellent heat resistance: carrier-free black masterbatches have excellent heat resistance and can maintain stable color and spectral properties under high temperature environment.

No carrier black masterbatch

Application areas of carrier-free black masterbatches

No carrier black masterbatches are mainly used in the following fields:

1. Plastic industry: Because of its excellent spectral properties, stability and heat resistance, carrier-free black masterbatch is widely used in plastic products, such as plastic containers, tubes, shoes and so on.

2. Coating industry: carrier-free black masterbatches can be used in coatings to improve color and gloss, maintain coating stability and wear resistance.

3. Rubber industry: carrier-free black masterbatch can be used in rubber products, can improve the blackness and uniformity of rubber, make the products more beautiful, also can improve the heat resistance, oxygen resistance and ozone resistance of rubber.

Third, no carrier black masterbatch preparation process

The preparation process of black masterbatch without carrier mainly includes the following steps:

1. Choose high-quality carbon black as raw material and add specific additives, such as stabilizers, leveling agents, etc., in order to improve the quality and stability of the product.

2. In the mixer or high shear mixer, mix the raw materials evenly.

3. The mixed raw materials are made into granules, which can be made by tablet presses, extruders and other equipment.

4. Screening and packing the granular non-carrier black masterbatches into finished products.