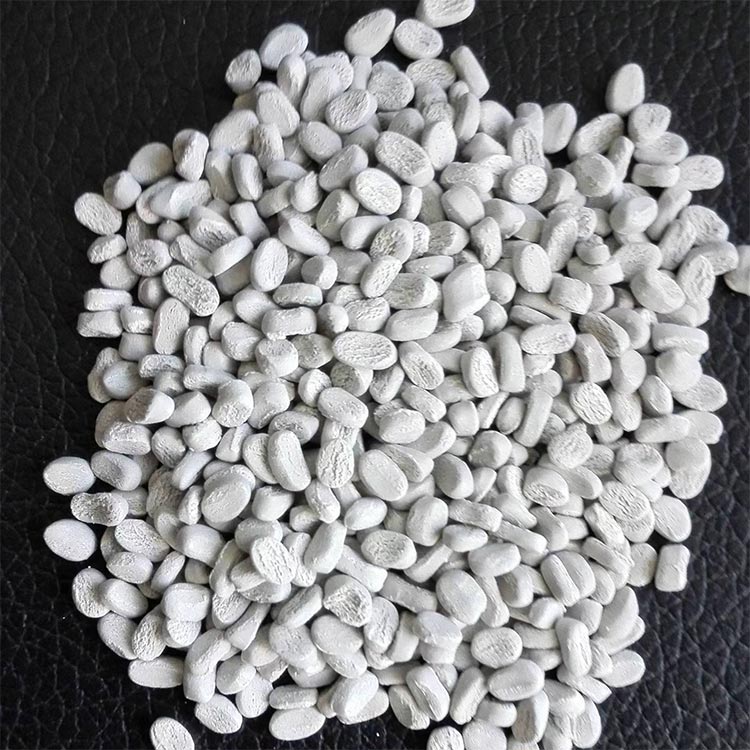

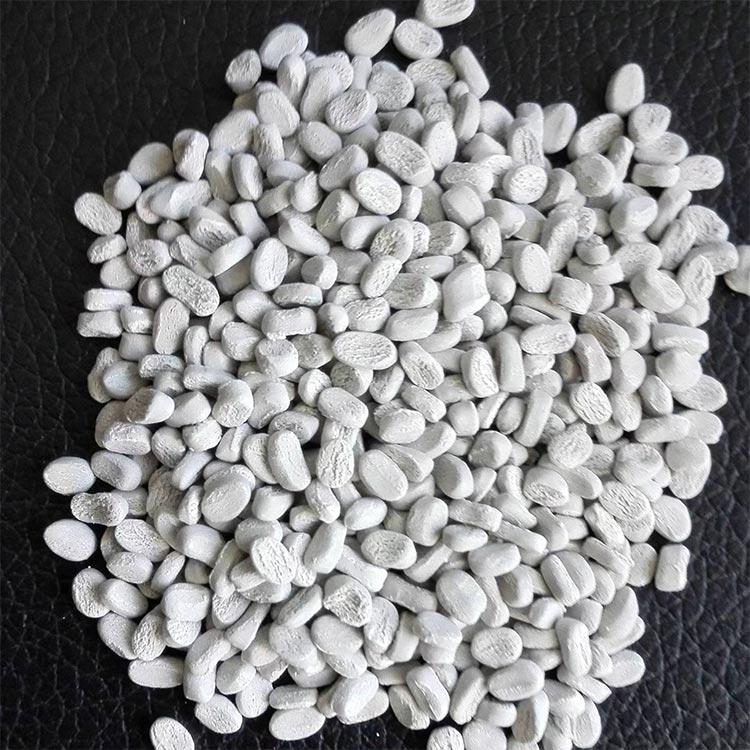

塑料消泡母粒

消泡母粒厂家告诉您塑料消泡母粒是一种用于塑料制品生产中的添加剂。它的主要作用是消除塑料中的气泡和气孔,从而提高制品的质量和美观度。

一、塑料消泡母粒的性质

塑料消泡母粒又叫做泡孔剂或消泡剂,是一种细小的颗粒状物质。它的主要成分是脱水氧化铝、硅酸钙、硅油等,具有以下几个特点:

1、消泡效果好。塑料消泡母粒能够有效消除塑料制品中的气泡和气孔,从而使制品表面光滑,密实度高。

2、化学性质稳定。塑料消泡母粒重金属含量低,化学性质稳定,不会在高温或潮湿环境下失去效果。

3、使用范围广。塑料消泡母粒可以用于各种类型的塑料生产,例如聚乙烯、聚氯乙烯、聚丙烯、聚酰胺等。

4、简单方便。塑料消泡母粒的使用非常简单方便,只需要将其混入塑料原料中即可。

二、塑料消泡母粒的应用

塑料消泡母粒在塑料制品生产中有着广泛的应用。以下是一些典型的应用场景:

1、塑料薄膜:在塑料薄膜的生产中,常常会出现气泡和气孔的问题。使用塑料消泡母粒可以有效解决这些问题,使薄膜表面光滑、透明度高。

2、塑料容器:在塑料容器的生产中,使用塑料消泡母粒可以使制品表面光滑细腻,同时还可以提高容器的耐压性能。

3、汽车内饰:在汽车内饰的制作过程中,使用塑料消泡母粒可以使制品表面光滑、细腻,同时还可以提高内饰的密封性。

4、电缆材料:在电缆的生产中,使用塑料消泡母粒可以使制品表面光滑、细腻,同时还可以提高电缆的耐压性能和安全性能。

三、塑料消泡母粒的制备方法

1、物料选择:制备塑料消泡母粒需要选择合适的原料,常见的原料有脱水氧化铝、硅酸钙、硅油等。

2、混合搅拌:将选好的原料按一定比例混合,在混合过程中需要进行充分搅拌,以保证各种原料能够均匀分布在整个混合物中。

3、造粒成型:将混合好的原料通过造粒机器进行成型,制成一定大小的颗粒状物体。

4、干燥包装:将成型好的塑料消泡母粒进行干燥处理,然后进行包装,保存在防潮、避光的环境中。

Defoaming masterbatch manufacturers tell you that plastic defoaming masterbatch is a kind of additive used in the production of plastic products. Its main role is to eliminate air bubbles and pores in the plastic, so as to improve the quality and aesthetics of the products.

First, the nature of plastic antifoam masterbatch

Plastic defoamer masterbatch is also called a foam pore agent or defoamer, which is a kind of fine granular material. Its main components are dehydrated alumina, calcium silicate, silicone oil, etc. It has the following characteristics:

1, good anti-foaming effect. Plastic defoaming masterbatch can effectively eliminate air bubbles and air holes in plastic products, thus making the surface of the products smooth and dense.

2, stable chemical properties. Plastic defoaming masterbatch has low content of heavy metals, stable chemical properties, and will not lose its effect under high temperature or humid environment.

3、Wide range of use. Plastic defoaming masterbatch can be used in various types of plastic production, such as polyethylene, polyvinyl chloride, polypropylene, polyamide and so on.

4, simple and convenient. The use of plastic defoaming masterbatch is very simple and convenient, only need to mix it into the plastic raw materials.

Plastic defoaming masterbatch

Second, the application of plastic antifoaming masterbatch

Plastic defoaming masterbatch has a wide range of applications in the production of plastic products. The following are some typical application scenarios:

1、Plastic film: In the production of plastic film, there are often bubbles and air holes. The use of plastic defoaming masterbatch can effectively solve these problems, so that the film surface is smooth and high transparency.

2, plastic containers: in the production of plastic containers, the use of plastic defoamer masterbatch can make the product surface smooth and delicate, but also can improve the pressure resistance of the container.

3, automobile interior: in the production process of automobile interior, the use of plastic defoaming masterbatch can make the product surface smooth, delicate, but also can improve the sealing of the interior.

4, cable materials: in the production of cables, the use of plastic defoaming masterbatch can make the product surface smooth, delicate, but also can improve the cable pressure resistance and safety performance.

Third, the preparation method of plastic defoaming masterbatch

1, material selection: the preparation of plastic antifoaming masterbatch need to choose the right raw materials, common raw materials are dehydrated alumina, calcium silicate, silicone oil and so on.

2, mixing and stirring: the selected raw materials are mixed according to a certain ratio, in the process of mixing needs to be fully stirred to ensure that a variety of raw materials can be evenly distributed throughout the mixture.

3, granulation molding: the mixed raw materials through the granulation machine for molding, made of a certain size of granular objects.

4, drying and packaging: the molded plastic defoamer masterbatch for drying, and then packaged, stored in a moisture-proof, light-proof environment.