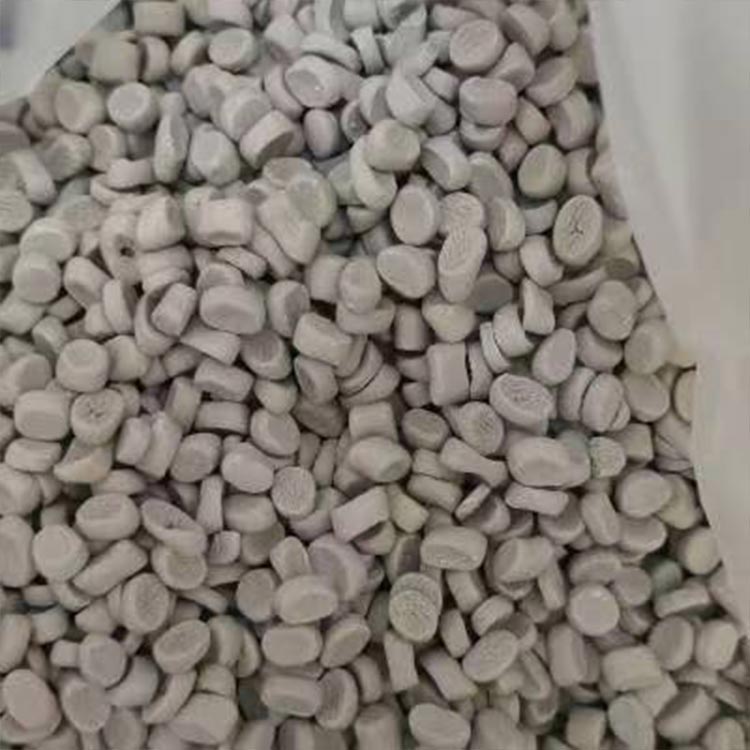

吹膜消泡母粒是一种用于生产塑料吹膜的原材料,用途广泛。

一、生产过程

吹膜消泡母粒是通过将树脂和添加剂混合均匀后,加入膨化剂、稳定剂等辅助剂,然后通过挤出机挤出成型,并通过旋转切断形成规格一致的母粒。加工干燥,包装出售。

二、性能特点

1.消泡效果显著:吹膜消泡母粒添加的消泡剂能够有效地消除吹膜过程中产生的气泡,提高产品质量。

2.塑化性能好:吹膜消泡母粒的塑化性能优良,易于加工成型,且成型后的塑料薄膜具有良好的柔韧性。

3.尺寸稳定性好:吹膜消泡母粒的切断尺寸稳定,避免了因尺寸不一致而产生的产品质量问题。

4.色泽明亮:吹膜消泡母粒经过挤出机挤出成型后,表面光滑且色泽鲜艳。

5.耐候性强:吹膜消泡母粒制成的塑料薄膜具有良好的耐候性能,不易受到氧气、紫外线、酸碱等环境的影响,长期使用不会出现老化现象。

三、应用领域

吹膜消泡母粒适用于生产各类薄膜产品,如保鲜膜、包装袋、塑料袋、农膜、建筑膜等。这些产品广泛应用于家庭生活、食品、医药、化工、建筑等领域。其中,塑料包装产品的生产和使用范围较广,市场前景广阔。

四、注意事项

1.储存:吹膜消泡母粒应储存在阴凉干燥处,避免阳光直射和潮湿,以免影响产品质量。

2.使用:在使用时,应注意控制加工温度,通常不宜超过200℃,以免影响消泡剂的效果。

3.包装:吹膜消泡母粒应采用防潮、防磨、耐压的包装袋进行包装,以免受到挤压和机械损伤。

吹膜消泡母粒是一种优良的塑料原材料,具有消泡效果显著、塑化性能好、尺寸稳定性好、色泽明亮、耐候性强等优点。在生产和应用过程中,需注意储存、使用和包装的问题,以保证产品质量和安全。

Blown film defoamer masterbatch is a kind of raw material used in the production of plastic blown film, which is widely used.

I. Production process

Blown film defoaming masterbatch is produced by mixing resin and additives evenly, adding bulking agent, stabilizer and other auxiliary agents, and then extruding through extruder, and rotating and cutting off to form masterbatch with consistent specifications. It is processed and dried, and packaged for sale.

Second, performance characteristics

1. Remarkable defoaming effect: the defoamer added to the blown film defoamer masterbatch can effectively eliminate the air bubbles generated in the process of film blowing and improve product quality.

2. Good plasticizing properties: blown film defoaming masterbatch has excellent plasticizing properties, easy to process and molding, and the plastic film after molding has good flexibility.

3. Good dimensional stability: blown film defoamer masterbatch cut size stability, to avoid product quality problems due to size inconsistencies.

4. Bright color: After blown film defoaming masterbatch is extruded by extruder, the surface is smooth and the color is bright.

5. Strong weather resistance: the plastic film made of blown film defoamer masterbatch has good weather resistance, not easy to be affected by oxygen, ultraviolet rays, acid and alkali, etc., and will not appear aging phenomenon in long-term use.

Blown film defoaming masterbatch

Application

Blown film defoaming masterbatch is suitable for the production of all kinds of film products, such as cling film, packaging bags, plastic bags, agricultural film, construction film and so on. These products are widely used in family life, food, medicine, chemical industry, construction and other fields. Among them, the production and use of plastic packaging products is wider, and the market prospect is broad.

IV. Precautions

1. Storage: Blown film defoaming masterbatch should be stored in a cool and dry place, avoiding direct sunlight and humidity, so as not to affect product quality.

2. Use: When used, attention should be paid to controlling the processing temperature, usually should not exceed 200 ℃, so as not to affect the effect of defoamer.

3. Packing: Blown film defoaming masterbatch should be packed in moisture-proof, abrasion-proof and pressure-resistant bags to avoid extrusion and mechanical damage.

Blown film defoaming masterbatch is an excellent plastic raw material, with significant defoaming effect, good plasticizing properties, good dimensional stability, bright color, weather resistance and other advantages. In the process of production and application, it is necessary to pay attention to the problems of storage, use and packaging to ensure product quality and safety.