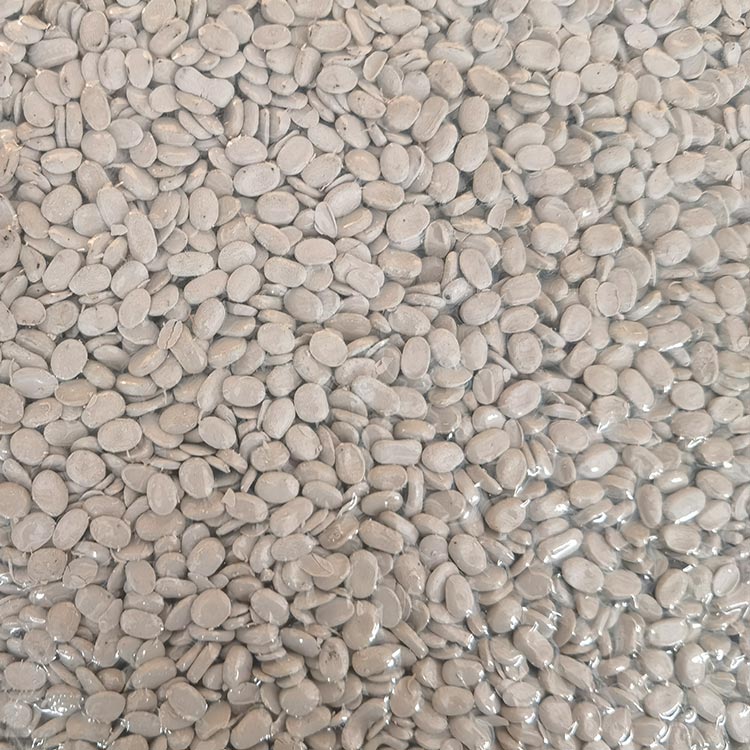

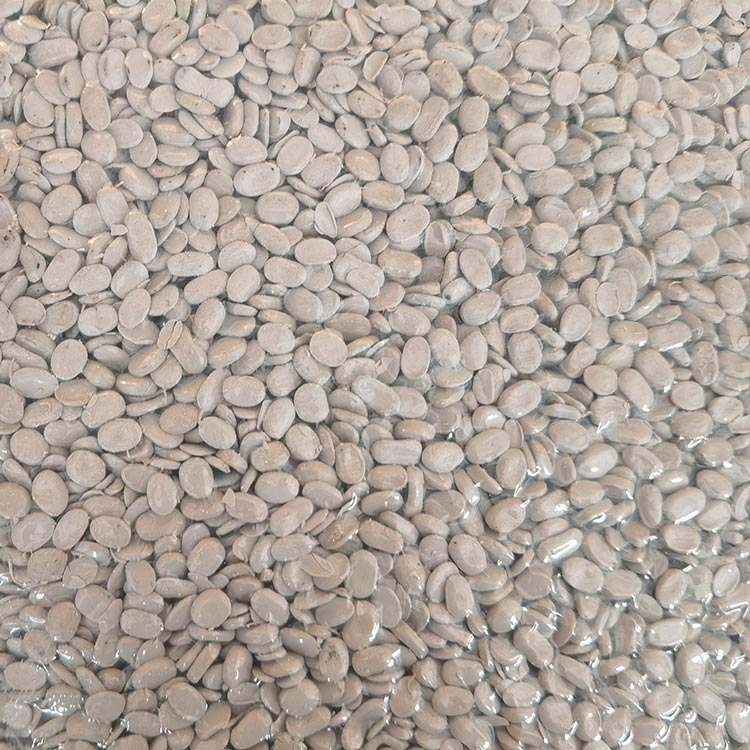

吸水消泡母粒

吸水消泡母粒是一种新型的高分子吸水消泡材料,其主要成分为聚合物及其衍生物。它具有吸水性、消泡性、分散性等特点,因为其广泛应用于制药、化妆品、食品、化吸水消泡母粒以其吸水、消泡和分散等颇具优势的特性,在化妆品、药品、食品和炼油等行业中得到了广泛应用。在制造化妆品时,通过添加该母粒可以使其更加光滑、柔滑和保持水分,达到了美化肌肤和改善使用感的目的。在制药行业中,该母粒可用于制造胶囊、片剂和药膏等制剂,对于改善药物的质地性质和效能方面有很好的帮助。在食品加工业中,吸水消泡母粒可以用于调配果汁、奶制品、调味汁等产品,使其具有较佳的口感和稳定性。在炼油行业中,该母粒广泛应用于煤气、石油和煤油的处理过程中,以清除其中的污染物和泡沫。工等领域中。

吸水消泡母粒是一种新型的高分子吸水消泡材料,其主要成分为聚合物及其衍生物。它具有吸水性、消泡性、分散性等特点,因为其广泛应用于制药、化妆品、食品、化工等领域中。

一、 吸水性

吸水是吸水消泡母粒的重要特性之一,它取决于母粒的化学成分和物理结构。该母粒具有一定的亲水性,因此可以迅速吸收周围环境中的水分,实现吸水的目的。不仅如此,它的吸水性还拥有很好的吸水速度和吸水量,这使得它广泛应用于化工、食品等行业,用于保水、调理粘度等方面。

二、 消泡性

吸水消泡母粒的消泡性是其独特之处之一,它可以有效地消除液体表面生成的气体泡沫,从而避免产品中的泡沫和气孔等缺陷,提高产品的质量和稳定性。这一特性使得该母粒在化妆品、药品、饮料加工和炼油等领域中得到广泛应用。

三、 分散性

吸水消泡母粒的分散性是指母粒在液体中均匀分散的能力。该母粒的独特结构使其具有较好的分散性,这意味着它能够很好地与液体相容,从而优化产品的混合程度,同时也有助于提高液体的流动性和稳定性。

四、 应用领域

吸水消泡母粒以其吸水、消泡和分散等颇具优势的特性,在化妆品、药品、食品和炼油等行业中得到了广泛应用。在制造化妆品时,通过添加该母粒可以使其更加光滑、柔滑和保持水分,达到了美化肌肤和改善使用感的目的。在制药行业中,该母粒可用于制造胶囊、片剂和药膏等制剂,对于改善药物的质地性质和效能方面有很好的帮助。在食品加工业中,吸水消泡母粒可以用于调配果汁、奶制品、调味汁等产品,使其具有较佳的口感和稳定性。在炼油行业中,该母粒广泛应用于煤气、石油和煤油的处理过程中,以清除其中的污染物和泡沫。

Water-absorbent defoamer masterbatch is a new type of polymer water-absorbent defoamer material, whose main components are polymers and their derivatives. It has the characteristics of water absorption, defoaming and dispersibility, because it is widely used in pharmaceutical, cosmetic, food, chemical and other fields.

I. Water absorption

Water absorption is one of the important characteristics of water-absorbent antifoam masterbatch, which depends on the chemical composition and physical structure of the masterbatch. The masterbatch has a certain degree of hydrophilicity, so it can quickly absorb the water in the surrounding environment to realize the purpose of water absorption. Not only that, it also has a very good water absorption speed and water absorption, which makes it widely used in chemical, food and other industries for water retention, viscosity adjustment and so on.

Antifoaming

The defoaming property of water-absorbent antifoaming masterbatch is one of its unique features, which can effectively eliminate the gas foam generated on the surface of the liquid, so as to avoid defects such as bubbles and air holes in the products, and improve the quality and stability of the products. This characteristic makes the masterbatch widely used in the fields of cosmetics, pharmaceuticals, beverage processing and oil refining.

Water-absorbing defoaming masterbatch

Dispersibility

The dispersibility of water-absorbing antifoaming masterbatch refers to the ability of the masterbatch to disperse evenly in the liquid. The unique structure of the masterbatch gives it good dispersibility, which means that it can be well compatible with the liquid, thus optimizing the degree of mixing of the product, and at the same time, it also helps to improve the fluidity and stability of the liquid.

Application areas

Water-absorbing and defoaming masterbatch has been widely used in the cosmetic, pharmaceutical, food and oil refining industries for its advantageous properties such as water absorption, defoaming and dispersion. In the manufacture of cosmetics, the addition of the masterbatch can make them smoother, more silky and retain moisture, so as to achieve the purpose of beautifying the skin and improving the sense of use. In the pharmaceutical industry, the masterbatch can be used in the manufacture of capsules, tablets and ointments, which is very helpful in improving the texture and efficacy of drugs. In the food processing industry, the water-absorbent defoamer masterbatch can be used to formulate products such as juices, dairy products, sauces, etc., so as to give them a better taste and stability. In the oil refining industry, the masterbatch is widely used in the treatment of gas, oil and kerosene to remove contaminants and foam from them.